The suspension system is a general term for all power transmission connection devices between the semi trailer frame and the axle to transmit forces and torque between the wheels and the frame. It also helps to buffer the impact force transmitted from the road to the frame or body and reduces the resulting vibration to ensure that the vehicle can operate smoothly. Usually, the semi trailer air suspension can be divided into four types.

Types of semi trailer suspensions

Rigid semi trailer suspension system

In the rigid semi trailer suspension system, the chassis of the vehicle can directly act on the axle semi trailer between the wheels, and there are no springs as buffers. When encountering uneven roads, the relative balance of the front and rear axles is entirely based on the swing of the balance beam. This type of suspension system is currently relatively rare because of its poor shock absorption effect and is mainly used on low flatbeds for low-speed cargo transportation.

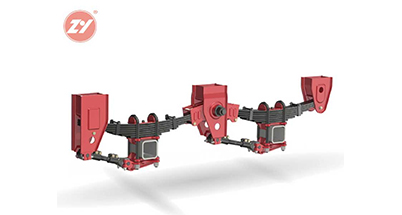

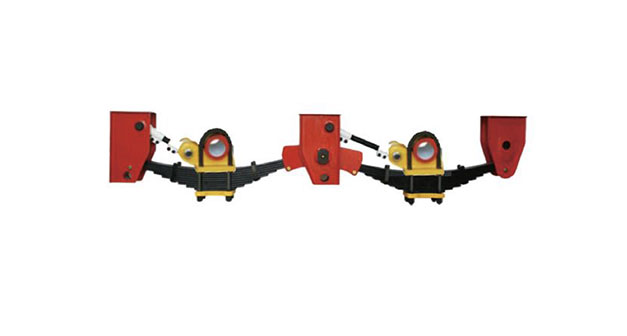

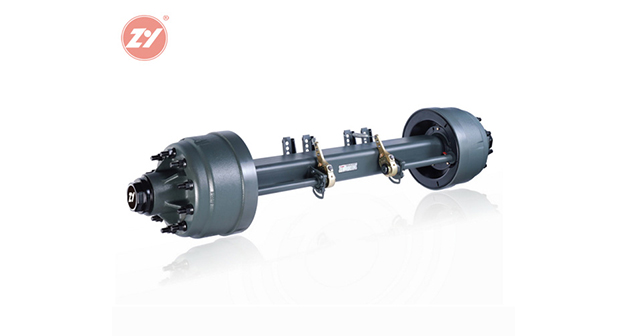

Steel plate semi trailer suspension system

It is actually the more common steel plate spring suspension system, mainly composed of steel plate springs, suspension system supports, connecting rods, U-bolts, and other components. One major advantage of this type of semi trailer suspension system is its low cost, reliable operation, and convenient maintenance. Because of this, the steel plate suspension system currently has the largest application proportion on semi trailers, at around 70-80%.

Single-point semi trailer suspension system

This is actually the more common steel plate spring front and rear support reduced to a single support connected to the vehicle body. It can distribute the force points to different types of axles, so the load-carrying capacity is a bit larger and generally used on heavy duty trailer suspension.

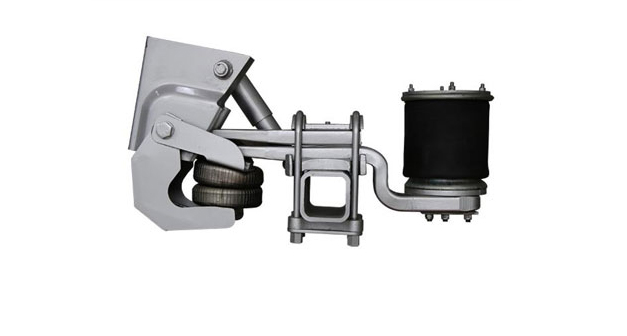

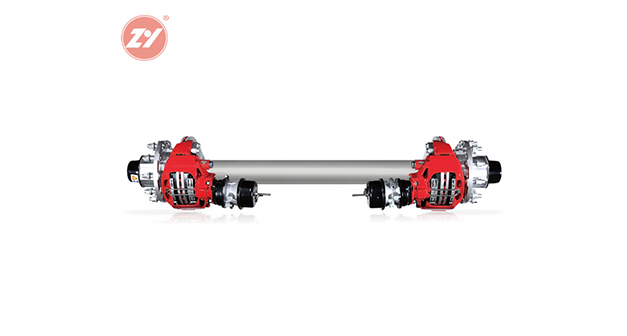

Trail air semi trailer suspension system

Also known as airbag suspension, its most distinctive feature is the airbag-like air spring. Compared with other suspension systems, the cushioning force of the trail air suspension system is better, which can effectively maintain the cargo and improve driving comfort. Currently, it is mainly used in the transportation of precision machinery, dangerous chemicals, and so on.

Advantages of trail air suspension

Good shock absorption effect. Compared with traditional steel plate springs, the airbags of the trail air suspension are obviously more soft and comfortable. They form a soft connection between the chassis and the axle, greatly relieving the bumps and shocks from the road. In addition to enhancing driving comfort, it also protects the cargo.

Reduce stress on the load. The compressibility of air enables the airbag to easily cope with the bumps on the road, while reducing the stress on the load, extending the service life of the axle and semi trailer and reducing vehicle costs to some extent.

Lightweight. Lightweighting is a development trend in the trailer accessories industry. Compared with other suspensions, the trail air suspension is lighter in weight, and standard users can obtain more spare weight space. For those who use the vehicle when empty, fuel can be saved, and energy efficiency enhanced.

Long service life. The quality of the air spring itself is relatively light, and the friction of the medium inside the airbag is also relatively small. The service life can reach 2-3 times that of steel plate springs, helping vehicle owners save costs effectively.