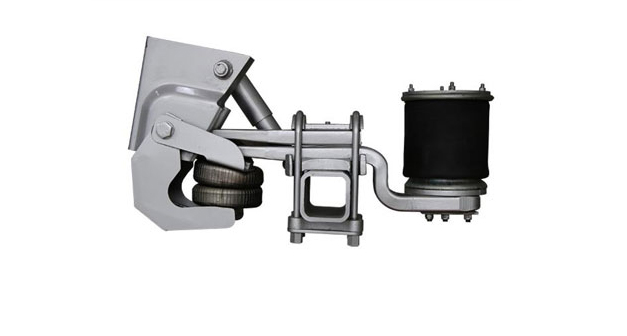

As the main component of the trailer suspension kits system, both air springs and air pillars are equipped with rubber airbags. Rubber is a natural product that is easily worn out, so airbags are usually the first part to wear out. Generally, rubber will dry and age, and during the operation of the air springs, the airbag will continuously stretch and contract up and down with the rolling piston, forming small cracks. During vehicle maintenance, it is recommended to check whether there are small cracks in the airbag. If there are, it is necessary to replace the air springs as soon as possible to avoid small cracks that may eventually lead to leaks over time.

High-quality air springs need to be replaced on average between six and ten years. External conditions such as climate, road conditions, and dust and road debris can also affect the function and life of these trailer suspension parts due to continuous wear and tear on the air springs. The lower the temperature, the harder the rubber and the poorer the elasticity, while high temperatures will accelerate the drying of the rubber. Both high and low temperature conditions can cause worn airbags to eventually burst.

Trail air suspension quality is a critical determinant of product life

In addition to rubber components, the materials of other parts such as press rings, O-rings, and pistons are also very important for product life. Although some cheap aftermarket air springs may look identical to OEM utility trailer air suspension, tandem axle air suspension and semi trailer air suspension in appearance, the actual differences may be significant! For example, using inferior rubber in piston design, lower-grade parts or components may result in reduced blast pressure, difficult installation, shock comfort damage, and roughness in noise, vibration, and sound vibration. Air springs and pillar assemblies are made from the highest quality rubber and other OEM-supplied parts from the entire vehicle, durable, and ensure safe driving.

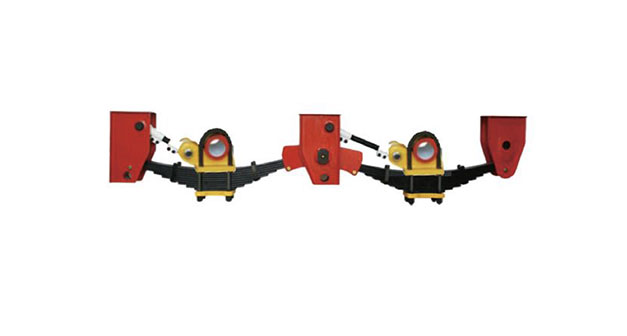

Replace trail air suspension in pairs

It is recommended to replace worn air springs and pillar assemblies in pairs. Even if only one side of the vehicle is leaking, it is recommended to replace the other side trail air suspension at the same time. Since the airbag of the other side air spring and pillar assembly is likely to be exposed to the same environmental conditions, it will also face the same wear and tear risks. If the trailer suspension kits are not replaced in pairs in a timely manner, the other side air spring and pillar assembly may also have similar leakage problems in the near future.

Repair shops usually recommend that car owners replace the traditional shock absorbers in pairs to avoid differences in shock absorption on both sides of the same vehicle axle. Similar old and new shock absorption differences also exist in trail air suspension pillars. If not replaced in pairs, the vehicle's driving, handling, and stability will be severely affected, resulting in unpredictable driving behavior and dangerous situations. For most products, pairing replacement is not mandatory, but only recommended. Because paired replacement can ensure driving safety, comfort, and also reduce the risk of vehicle maintenance.