With the development of automotive technology, people's demands for the comfort and operability of cars are getting higher and higher. Suspension is one of the important configurations for the comfort and operability of cars and has become a popular choice for consumers, as well as an important configuration for various manufacturers to compete for high-end market.

Trail air suspension is widely used in heavy-duty trucks and buses in commercial vehicle sector, while electric control air suspension is mainly used in passenger cars due to its high cost. However, with the continuous improvement of domestic replacement and technology, the price of suspension and its application in models have rapidly dropped. In addition, the increasing demands brought by consumer upgrading and the weight and mileage sensitivity of new energy vehicles have also promoted the wider application of air suspension.

Automotive air suspension is a connection device between the car body and wheels

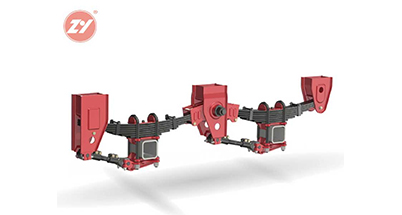

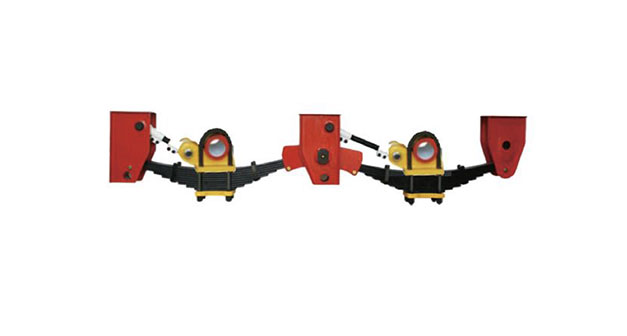

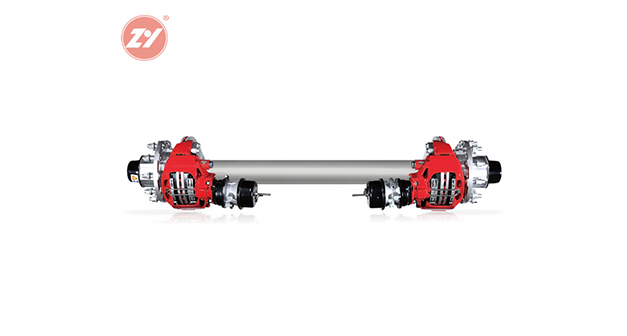

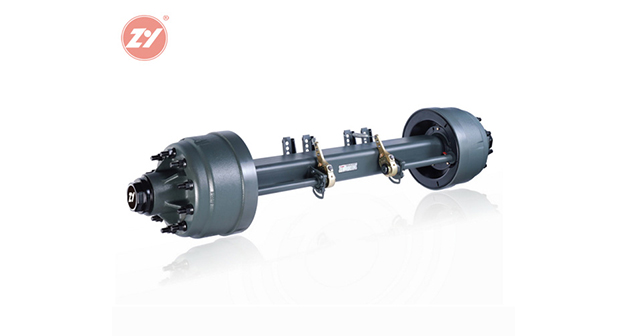

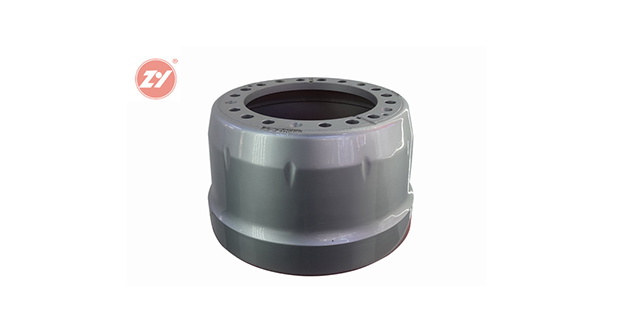

The main function of utility trailer air suspension, tandem axle air suspension and semi trailer air suspension is to transfer the torque between the car body and wheels, such as the supporting force, braking force, and steering force, and also reduce the impact of rough roads on the car body, absorb the vibration generated by the wheel movement, ensure the comfort of car riding and reduce the loss of goods transportation. Usually, the structure of the car suspension consists of elastic elements, shock absorbers, and guide mechanisms, which respectively play the roles of buffering vibration, absorbing vibration, and transferring torque.

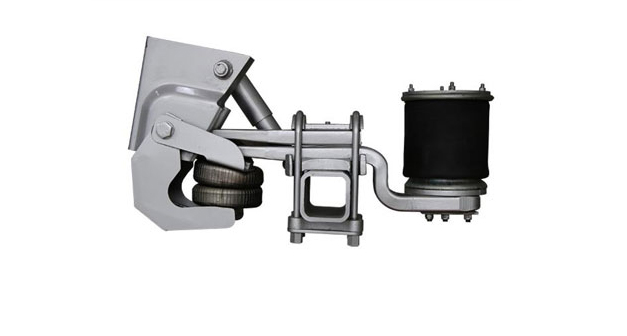

Elastic elements and shock absorbers jointly constitute the damping system of the suspension, which is the most important component in the car suspension system. Elastic elements have a certain buffering effect, which can extend the action time of the impact, reduce the force per unit time, and achieve the effect of buffering. Shock absorbers can absorb energy, convert the kinetic energy of the impact into heat energy, consume excess vibration, and achieve the effect of damping. The elastic element and shock absorber are generally placed in parallel. During the compression and rebound of the elastic element, the shock absorber simultaneously absorbs energy. Afterwards, the elastic element returns to its original length and supports the vehicle at normal height. In order to improve comfort, air suspension system is gradually applied to the damping technology of cars.

Air suspension system as a semi-active suspension

The air suspension system can control the chassis height, body tilt angle, and damping coefficient, etc., which can significantly improve the driving experience, increase ride comfort, and enhance the intelligence level of the car chassis. The air suspension system is mainly composed of independent air springs, body acceleration sensors, air spring shock absorber assemblies, air suspension controllers (ECU), air tanks, air supply systems, distribution valves, and suspension height sensors, which is a combination of chassis system calibration, electronic control, and rubber technology.