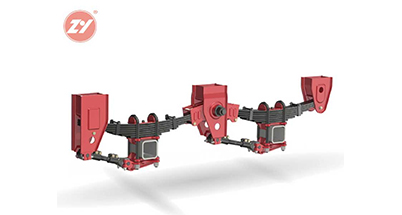

The axle is the most important set of components in a trailer, directly related to the vehicle's load capacity, braking, and driving. If there is a problem with the axle, the safety, attendance rate, and economic benefits of the vehicle are almost meaningless. Therefore, it is particularly important to do a good job in the installation and maintenance of the axle.

In fact, there are many precautions in the installation and maintenance of the selected axle products for special vehicle enterprises. Correct installation methods and regular maintenance can keep the vehicle in good working condition and ensure better performance and safety. This article takes the axle semi trailer as an example to systematically explain the installation and maintenance of the axle.

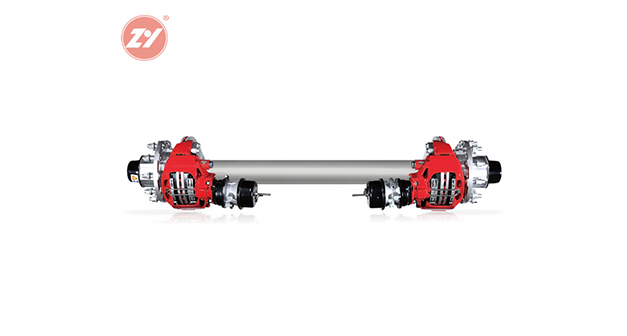

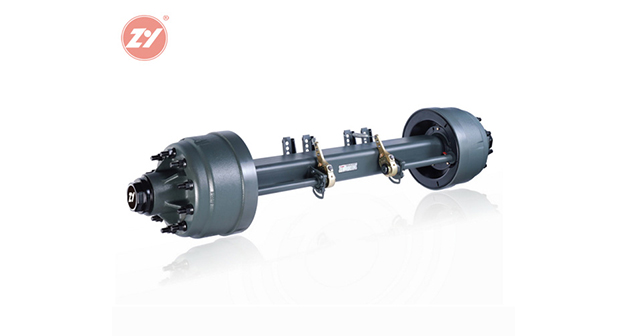

Installation of semi trailer axles

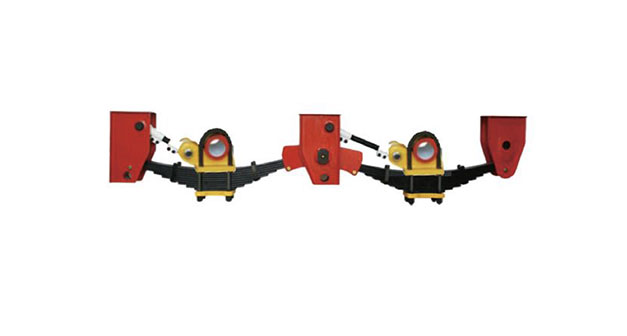

Welding of spring bracket and axle:

The spring bracket is the place where the semi trailer axle bears the maximum bending stress, so the welding quality of the spring bracket and the axle is particularly important, and the welding quality will directly affect the service life of the axle.

Focusing on several issues related to the welding of the spring bracket and the shaft body:

Whether the spring bracket and the shaft body are tightly fitted, if they are not tight, they need to be corrected before the welding;

The position of the spring bracket on the shaft body should meet the requirements of the positioning center distance;

The welding ground wire can only be connected to the shaft body and cannot be grounded through the rotating member of the wheel to prevent the bearing from being electrically ignited and damaged.

Tightening of the axle bolts:

After the new vehicle is loaded and runs, after 15 days of driving, or every time the tire is replaced, use a torque wrench to tighten the nuts in the order specified to the specified value.

For bolts, first remove the rounded nuts on the wheel, use a torque wrench to tighten the cup-shaped nuts to the specified value, and then tighten the rounded nuts to the specified value.

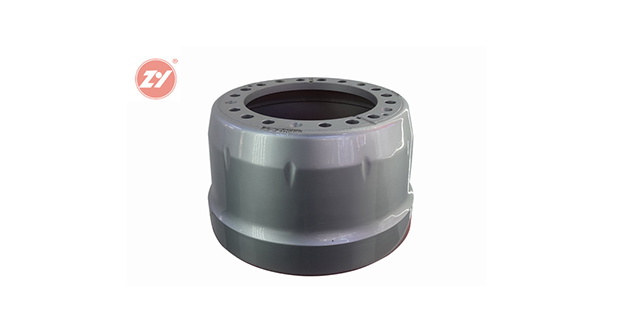

Maintenance of the semi trailer axle lubrication system

The following maintenance issues need to be noted for the lubrication system of the semi trailer axle:

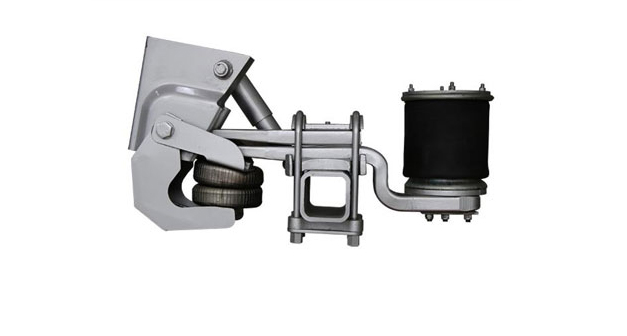

The lubrication system of the semi trailer air suspension is divided into grease lubrication system and oil lubrication system, and it is recommended to use lubrication products suitable for different systems. The grease lubrication system requires a No. 2 composite lithium-based grease that is suitable for temperatures between -30℃ to 180℃, and it is recommended to use special grease oil packages or lubricants. The amount of grease used for each shaft is about 1.2 to 1.5 kg. The lubricating oil for the oil lubrication system should use 80W-90 gear oil, and it is recommended to use special lubricating oil packages or gear oil.

For the camshaft bush and the brake adjustment arm, add lubricating grease every three months until new grease overflows around the oil nozzle. Regular addition of grease helps reduce mechanical wear and tear.

Clean the inner cavity of the hub and the inner cavity of the hub end cover, and then add lubricating grease. The amount of lubricating grease injected into the hub cavity is 0.4-0.57 kg. The clearance between the inner ring rollers of the bearing must be filled with lubricating grease. It is recommended that users replace the new hub oil seal every time the hub bearing is disassembled to obtain better sealing performance.