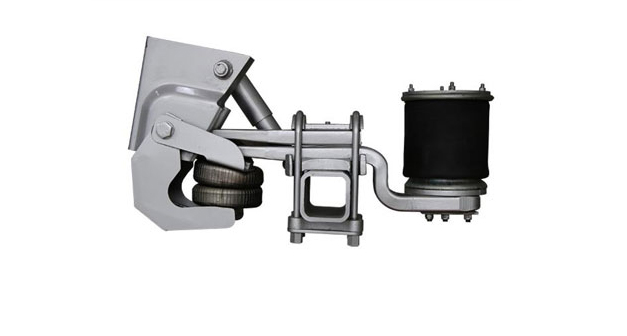

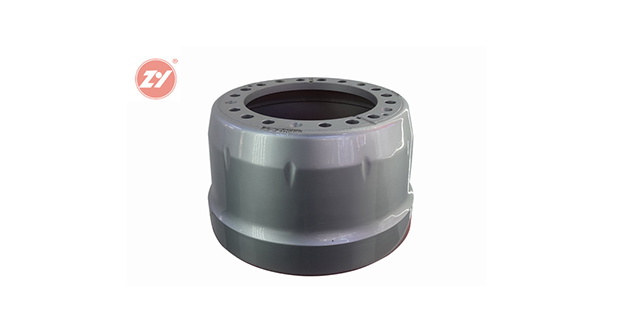

The brake drum is the basic part of the vehicle wheel brake, usually made of 14 or 18 gray cast iron, or malleable iron. When the drum brakes trailer is damaged, it is mainly due to the wear and deformation of the friction pad of the brake system and the brake drum. Especially when the rivet head of the brake system friction plate is exposed, or the hard material such as sand enters the brake, the wear of the brake drum is more serious at this time. When the brake drum cracks, what causes it?

Causes of cracks in the brake drum

The brake drum exceeds the size of the application limit due to wear, and after repeated boring processing, the drum wall becomes thinner, and cracks appear under the action of load stress. If the size of the inner diameter of the brake drum exceeds the application limit, the vehicle will wading immediately after driving downhill or downhill with heavy load, which will cause the brake drum to shrink sharply after high temperature, causing cracks on the friction surface of the brake drum such as the inboard rear brakes along the axis direction. It should be pointed out here that some units add metal plates to the brake system shoes to increase the thickness of the brake system friction pads after the brake drum and inner diameter have exceeded the application limit, which is very dangerous.

Daily maintenance method of brake drum

During the secondary maintenance of the vehicle trailer manufacturing parts, if the brake drum is found to be cracked during the cleaning inspection, it should be resolutely replaced, so it is also very necessary to do the maintenance work of the brake drum in peacetime. Vehicle braking relies on the braking force generated by the friction between the brake drum and the brake system shoe friction plate to make the vehicle decelerate or stop. Long-term application, the brake drum wears and causes grooves and strains on the inner surface of the brake drum. Choosing brake fluid can also play a role in smart maintenance of the brake drum! Most of the automotive applications of hydraulic brake systems are alcohol-based brake fluids, and the alcohol contained in them is easy to volatilize. If the system is braked frequently, it is very easy to increase the temperature of the brake system pipeline and cause air resistance, which will cause the brake system to fail. The use of brake fluid with high boiling point and not easy to deteriorate can greatly improve the safety factor of driving.