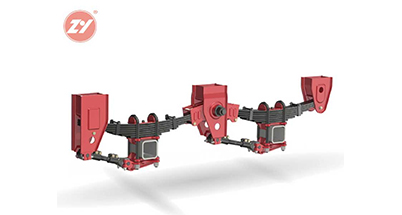

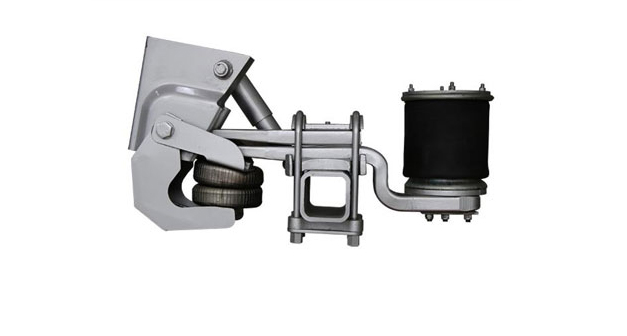

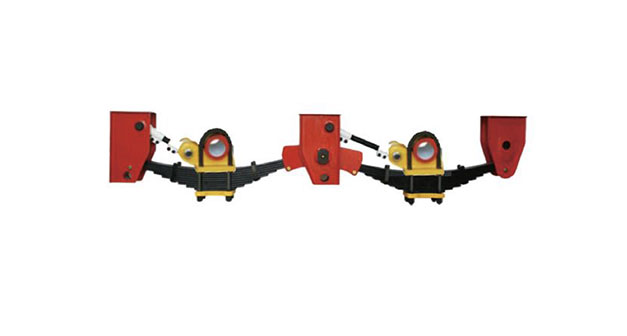

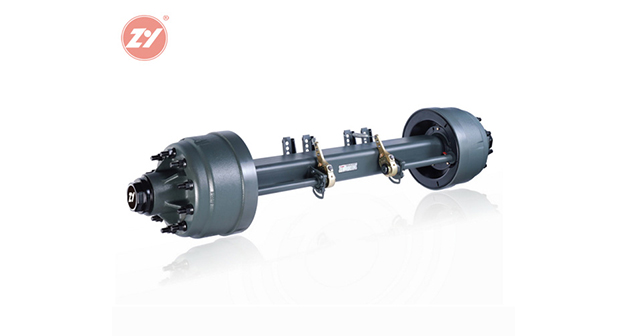

Common cars in life have 4 tires, each pair of tires is connected by an axle, that is to say, the number of axles of the car is 2. The axle is connected to the frame (load-bearing body) through the suspension, and wheels are installed at both ends. The function of the off road trailer axle is to carry the load of the car to maintain the normal driving of the car on the road.

Ⅰ. The working principle of the off road trailer axle

The half shaft of a car is the drive shaft. The car needs to turn after walking, and the rotation of the wheels on both sides is different, one side is faster and the other side is slower, which requires a differential on the drive shaft. The differential is a device that makes the wheels on both sides turn at different speeds, and the half shafts are connected to the differential and then to the wheels; The torque and rotational speed distributed by the differential are transmitted to the wheels to drive the wheels to rotate. In general construction machinery such as loaders, cranes, etc., the rotational speed transmitted from the axle shafts is further decelerated by the wheel side reducer to increase the torque and make the wheels have a stronger driving force. The wheel reducer is a planetary gear reducer.

When the piston moves up and down once, the engine will vibrate twice, so the vibration frequency of the engine is related to the speed of the engine. In vibration theory, multiple harmonic vibrations are often used to describe the vibration of the engine. The vibration frequency with the same frequency as the engine speed is called first-order vibration, and the frequency is twice the engine speed is called second-order vibration, and so on. There are also third-order vibrations, fourth-order vibration. However, the higher the vibration frequency, the smaller the amplitude, and the second order and above can be ignored. Its first-order vibration accounts for more than 70% of the entire vibration and is the main source of vibration.

Ⅱ. The reason for the abnormal sound of the off road trailer axle

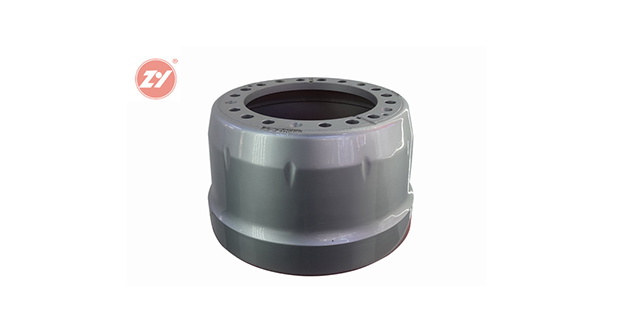

1. Unbalanced sound of the drive shaft: a periodic sound that can be heard when the car is driving, and the faster the speed, the louder the sound. In severe cases, the body will tremble, and the steering wheel will feel numb. To check the sway of the off road trailer axle kits, if the sway is the largest when the speed drops, it means that the sway and noise are caused by the unbalanced transmission. If the noise is not serious, it can be driven back and repaired. If it is serious, it should be stopped immediately for repair.

2. The drive shaft and universal joint make loose noise: when the car starts, the body trembles, and the impact sound of "click, click" can be heard, and the sound is more obvious with the change of vehicle speed during driving. Shake the axle of the transmission car by hand, if the spline teeth and spline grooves are worn, there will be a loose feeling. Release the hand brake and shake the hand brake disc back and forth by hand. If there is a gap, it means that the spline teeth of the second shaft of the transmission and the spline groove of the flange are worn and loose.

3. The sound of the intermediate bearing of the transmission shaft: There is a kind of "woo, woo" sound when the car is driving. The faster the speed, the louder the sound, and the sound is extremely obvious when the vehicle is coasting in neutral. When a noise is found in the intermediate bearing, you should first check whether the bearing position is skewed. If it is not deflected, the bracket should be removed for disassembly inspection to see if the bearing is too worn, or if there is a lack of lubricating oil, and if the bracket rubber sleeve is damaged. Repair or replace as necessary.

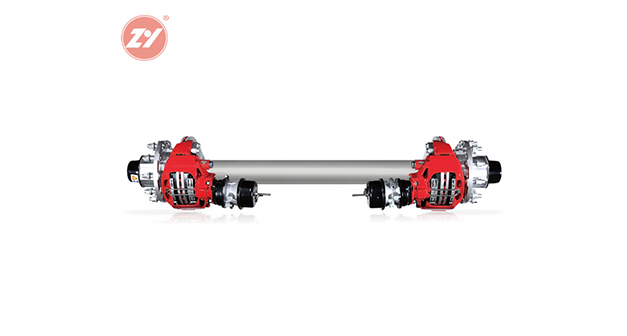

The advanced trailer spares and axle and the wheel of the car are connected by splines. There is a universal joint at each end of the half shaft. The splines are connected. One end is connected to the wheel shaft, and the other end is connected to the output end of the gearbox. The two half shafts drive the two wheels. Because of the universal joints and splines, the wheels can be turned by an angle without affecting the transmission of power to the axles.