Due to the complexity of the structure, the cost of trail air suspension is much higher than that of ordinary suspension, and a set of expensive trail air suspension typically has a lifespan of only 5-10 years under normal circumstances. Furthermore, in order to maintain good suspension performance, regular maintenance at a 4S store is required, which increases the cost of car manufacturing and maintenance. This does not align with the market positioning of ordinary household cars, so only luxury cars that pursue comfort are equipped with trail air suspension.

A brief introduction to trail air suspension

There are two very important parts in car suspension: dampers and springs. The role of the damper is to quickly absorb the vibration transmitted to the wheels from the road, while the main function of the spring is to support the weight of the car body and cushion the vibrations from the wheels.

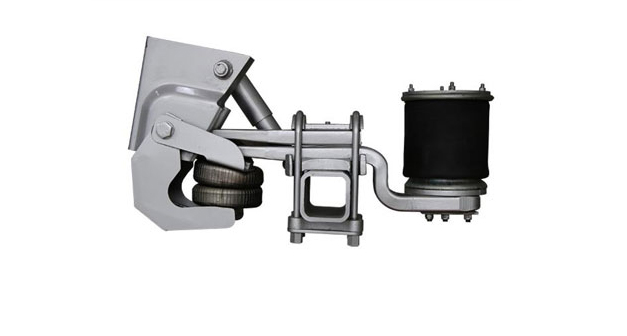

There are two main types of springs in car suspension: the common steel coil springs and the air springs. Air springs are mainly made up of rubber bags, and if air springs are used in the suspension, we generally call this type of suspension trail air suspension.

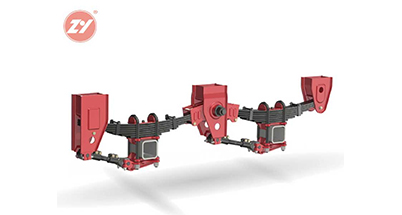

Trail air suspension is mainly composed of air, springs, dampers, height sensors, controllers, air compressors, and air tanks. The air compressor is used to inflate the air tank and keep it at a certain pressure. The air tank mainly stores high-pressure gas, and its most important function is to inflate the airbags. The height sensor is used to monitor the posture of the vehicle and tell the controller the current status of the vehicle. The controller then controls the inflation and deflation of the airbags according to a pre-prepared control strategy, thus adjusting the height of the vehicle.

When it is necessary to raise the vehicle height, the controller directly inflates the air springs by controlling the air tank, rather than directly injecting gas into the air springs through the air compressor. This is because the air compressor produces some noise when working, and frequent use can result in a shorter service life for the compressor. Therefore, the air compressor will first inject gas into the air tank. When the pressure inside the air tank reaches a certain level, the compressor stops working. The process of exhausting the air springs is relatively simple, relying on the weight of the vehicle to expel the gas from the air springs.

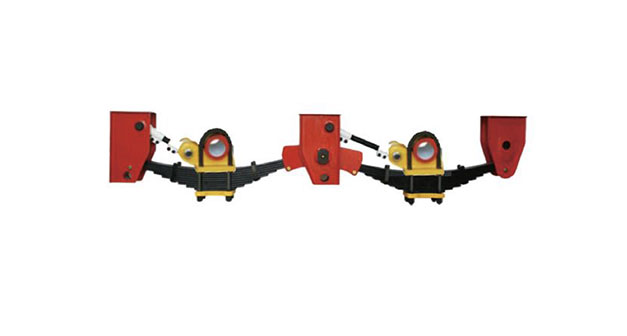

Utility trailer air suspension, tandem axle air suspension and semi trailer air suspension gives cars more flexibility. When driving at high speeds, the suspension can become harder to improve the stability of the vehicle, while during long drives on uneven roads at low speeds, the control unit will soften the suspension to improve the comfort of the car.

Advantages of trail air suspension

The height of the vehicle can be improved by inflating and deflating the air springs, which can improve vehicle clearance and enhance vehicle passability; while driving, lowering the height of the car can improve the stability of the vehicle, and lowering the height of the car when stationary can also make getting on and off the car easier.

As the air spring contains gas, which is compressible, the isolation effect is better than that of steel springs. When encountering shocks on uneven roads, many small vibrations are not easily transmitted to the interior of the car through the air spring, thus improving the overall comfort of the car.

The stiffness of the air spring can be improved by increasing the pressure of the gas inside the spring, thereby improving the load-bearing capacity of the vehicle.