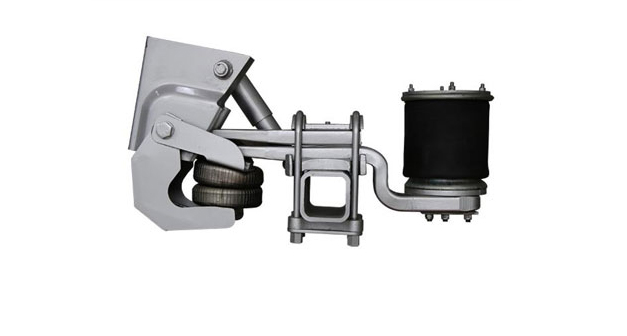

The core component of trail air suspension is the air spring, whose name originates from the English term "Airspring." Air springs replace metal springs by filling compressed air into rubber bags to achieve necessary rigidity. Let's take a look at the introduction of trail air suspension system-related knowledge.

Functions of trail air suspension system

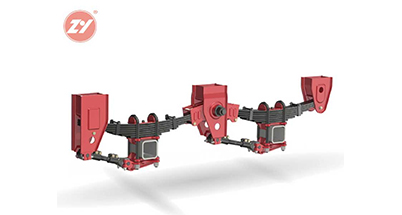

The trail air suspension system is a general term for all force transmission connecting devices between the frame and the axle or wheel of a vehicle. Its function is to transmit force and torque between the wheels and the frame, cushion the impact force transmitted to the frame or body by uneven road surfaces, and dampen vibrations generated, ensuring the vehicle travels smoothly.

Operating principle of trail air suspension system

The working principle of trail air suspension is to use an air compressor to compress air, then develop and change the compressed air to send it to the air chamber of the spring and shock absorber, changing the height of the trailer. There are horizontal height sensors near the front and rear wheels. According to the output signal of the horizontal height sensor, the trail air suspension control unit determines the change in the height of the vehicle body and adjusts the compressor and exhaust valve to compress or stretch the spring to use as a shock absorber.

Current applications of trail air suspension system

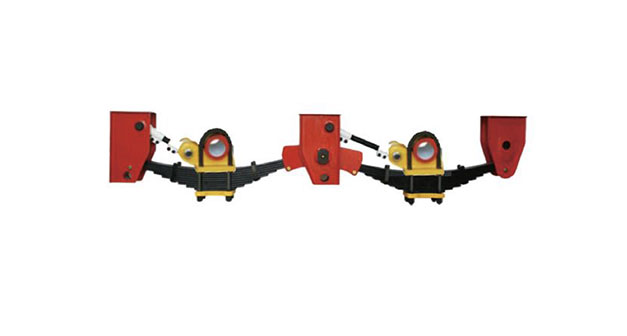

In the past decade, trailer accessories trail air suspension has become a popular culture. Almost all kinds of vehicles, including modified cars, trucks, regular cars, and even motorcycles, can install air springs. These adjustable suspensions can make the trailer very close to the ground and lift the body to increase the pass rate when passing obstacles or climbing hills. Current trail air suspension systems usually use a small electric motor or engine to drive an air compressor to pre-compress air for the air tank, directly saving time to compress air when adjusting the suspension. The size of the air tank is carefully calculated and related to the output of the air compressor, standard atmospheric pressure, and compression pressure.

More aggressive trail air suspensions that use nitrogen or carbon dioxide-filled industrial high-pressure gas cylinders can also be used. Basically, these two gases can independently adjust the air pressure of a single suspension, allowing the trailer to tilt up and down front and rear; in some cases, suspension can be performed through a single wheel, and even the entire trailer can jump.

Trail air suspension system manufacturers do not think this is a strange species for friends. Tandem axle air suspension, utility trailer air suspension, and semi trailer air suspension have become a paving device on pickups, off-road vehicles, buses, and trucks, installed in front and rear of conventional suspension components to increase the carrying capacity of the trailer. One major advantage of trail air suspension in cargo transportation applications is that the trail air suspension can be deflated to reduce the height of the vehicle body, reducing the workload of workers loading and unloading cargo.